|

Think & Tinker, Ltd.

P.O. Box 1606, Palmer Lake, CO 80133 Tel: (719) 488-9640, Fax: (866) 453-8473 Sales: Sales@thinktink.com, Support: Support@thinktink.com |

||||

|

Think

& Tinker Ltd.   SkypeMe at "thinkntink" |

PREVIOUS

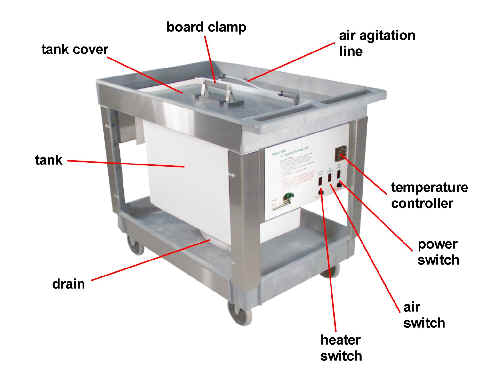

Peroxy-Sulfuric Etching ModuleOverview/Cart Components Overview Your Think & Tinker GC18-2000 Peroxy-sulfuric etching system has been thoroughly tested at the factory. Although the unit arrived at your facility completely assembled, there are a few things that you need to do to get it ready to use. There are a number of possible configurations for the cart-based systems so some of the sections below may not apply to your unit. Etching Cart Components  Bubble Agitated Etcher Cart Fig. 1 The corrosion resistant cart is molded from polyethylene and polypropylene. Stainless steel trim and structural panels eliminate sagging and increase the load carrying capacity to well over 500 pounds (228 kg). Heavy-duty casters allow the cart to be moved to any location in your shop so that workflow can be altered to adjust to your changing needs. The primary purpose of the cart is to act as a mobile mounting platform for all of the components needed to make a self-contained electrochemical etching system. These components / capabilities include:

Before jumping in, it is a good idea to review a few basic safety principles. PREVIOUS

|

|||

|

||||

Home

Home