|

Think & Tinker, Ltd.

P.O. Box 1606, Palmer Lake, CO 80133 Tel: (719) 488-9640, Fax: (866) 453-8473 Sales: Sales@thinktink.com, Support: Support@thinktink.com |

||||

|

Think

& Tinker Ltd.   SkypeMe at "thinkntink" |

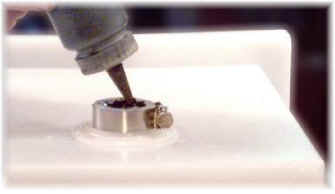

PREVIOUS

Peroxy-Sulfuric Etching ModuleMaintenance/Leaky Connection Maintenance There is not a lot that can go wrong with the etching cell or mounting cart. Sounds like famous last words to me. Fixing a leaky connection Based on past experience, it is very unlikely that you will ever have to repair a leak in this system. All of the joints and fittings are sealed with a specially formulated liquid vinyl (Liquid Duct Tape®, LDT®) that stays flexible and resists the corrosive effects of the etchant. Nonetheless, it is beneficial to take a look at how each threaded connection is made so that you can repair or replace a fitting if necessary. For the sake of demonstration, assume that one of the threaded connections has sprung a leak. Put on your safety glasses and chemical resistant gloves.  Applying LDT to a female fitting Fig. 6

Assembled welded boss-fitting Fig. 7

"What the heck", you might ask "is this all about?" Well, I´m glad you asked. When you thread the two fittings together, the two bands of LDT® (one in the female threads, one on the male side) will be pushed ahead of the threads (inside and outside of the fitting) and form rings of vinyl on either end of the seal. Meanwhile, some of the LDT® is smeared along the entire length of the threads inside the sealed area to fill in any pits or scratches. When the LDT® dries, you end up with a VERY secure seal that can be easily taken apart later if modifications or further repairs are necessary. Experience has shown that threaded couplings sealed using this technique will provide many years of leak-free service. PREVIOUS

|

|||

|

||||

Home

Home